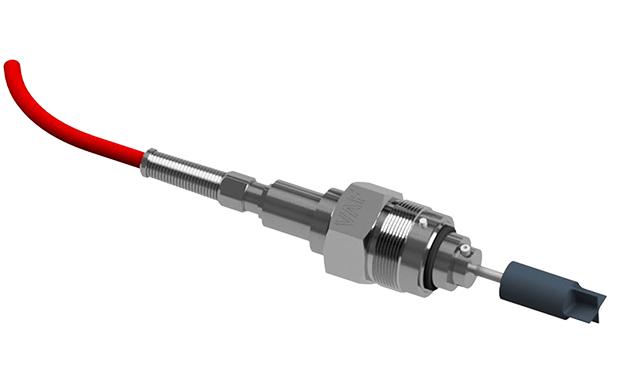

The ViscoSense®3 is an advanced in-line viscosity sensor designed for high-accuracy measurement and control of fuel viscosity in maritime and industrial applications. Utilizing a patented torsional vibration technology, it ensures reliable, real-time monitoring without being affected by external factors such as flow velocity, vibrations, or dirt particles.

Optimizing Fuel Efficiency

Fuel oil quality varies, making viscosity control critical for efficient combustion. The ViscoSense®3 ensures the ideal fuel viscosity, leading to better atomization, complete combustion, and reduced deposits, ultimately extending engine lifespan and improving overall performance.

Built for Reliability

Engineered to operate under the most demanding conditions, the ViscoSense®3 offers long-term stability with no recalibration required, making it a durable and cost-effective solution for fuel management.

Features

- Stable and accurate in-line measurement.

- Torsional vibration measuring principle.

- No moving parts.

- Minimal load on components.

- Stainless steel 316L pendulum.

- Smooth edged pendulum.

- Compact light-weight construction.

- Calibrated for life.

- Type approval from all major classification authorities.

- Local readout on sensor

- No wear parts that need maintenance

- Full digital integration into the VAF onboard SPU3 data collection system

- Obstruction-free measurement. No liquid filtering needed

- Intuitive operation. No training needed

- Maintenance free design

- Design simplicity. Only few spare parts

Show all applications

Benefits

- Optimal burning efficiency and fuel consumption.

- Electronics can be separated from a hot or aggressive environment

- Reliable under all circumstances

- Not influenced by vibrations, flow velocity or dirt particles

- No preventive maintenance required

- Low operating costs

- No ageing and wear effects

- Durable

- Insensitive to adherence

- Easy to install

- Long and trouble-free operation

- To be implemented directly on any ship without additional costs

- Local readout on sensor

- No wear parts that need maintenance

- Full digital integration into the VAF onboard SPU3 data collection system

- Obstruction-free measurement. No liquid filtering needed

- Intuitive operation. No training needed

- Maintenance free design

- Design simplicity. Only few spare parts

Show all benefits

Applications

- Marine applications

Marine applications In-line viscosity control is required when (ships) diesel engines or – burners are operated on (heavy) fuel oil, since there is a large variety in quality of this fuel. A correct viscosity ensures an optimal burning efficiency of the fuel, and therefore reduces operating and maintenance costs. Mass flow measurement enables to monitor fuel consumption in kilograms instead of litres. This can be realised by combining ViscoSense®3D density measurement with a positive displacement Flowmeter, which assures best possible accuracy

- Industrial applications

The ViscoSense®3 sensor is also suitable for the in-line measurement of viscosity of many liquids in industrial applications. In addition, the ViscoSense®3D sensor is suitable for density measurement. Because individual applications need special attention please contact VAF Instruments for a tailor made solution.

- Local readout on sensor

- No wear parts that need maintenance

- Full digital integration into the VAF onboard SPU3 data collection system

- Obstruction-free measurement. No liquid filtering needed

- Intuitive operation. No training needed

- Maintenance free design

- Design simplicity. Only few spare parts

Show all features

Short specifications Sensor

| Viscosity range | 0-25/50 mPa.s (other ranges on request, max. 1000 mPa.s) |

| Density range* | 750-1100 g/l (standard, other ranges on request) |

| Temperature range | 0- 200°C |

| Maximum operating temperature | 180°C |

| Temperature transmitter | PT100 element |

| Viscosity accuracy | ± 2% instantaneous or 0,5 mPa.s |

| Density accuracy* | ± 0,1% instantaneous or 1 g/l |

| Temperature accuracy | ± 1°C |

| Sensor material | Stainless steel 316L / Ni-alloy* |

| Coating material | Diamond Like Carbon (DLC) |

| Protection class | IP65 |

| Cable lenght | 5 m integrated |

| Weight | 1 kg |

Did you know

20% FUEL SAVING ALL IN SOLUTION

Learn how our tools and expertise make meeting ShaPoLi regulations easy and efficient. Schedule your demo now to ensure seamless compliance and sustainable operations!

100% compliance SOLUTION

Learn how our tools and expertise make meeting ShaPoLi regulations easy and efficient. Schedule your demo now to ensure seamless compliance and sustainable operations!

Why choose VAF

VISCOSENSE

With decades of experience VAF Instruments is the worldwide market leader for in-line viscosity measurement and control systems. ViscoSense®3 and ViscoSense®3D are the latest innovative developments in a long history of outstanding viscosity sensors for fuel oil applications. In this most demanding environment of diesel engines on board ships and in land based power plants, VAF Instruments has proven itself with high quality products and a comprehensive and professional customer support.

VAF Instruments is the most preferred supplier of the top 100 shipyards and market leader in maritime measurement systems today because we continuously strive to improve our products and service in order to serve you better.

For one, VAF Instruments offers our customers the best, longest and most comprehensive guarantee in the maritime industry. Secondly, with a global service organisation, VAF Instruments offers a unique level of customer service. When you look for reliability and service, VAF Instruments is the logical choice.

VAF Instruments is the leading specialist for the development, manufacturing and world-wide sales of measurement and control systems. We supply both the marine- and process industry.

Having more than 80 years of experience with flow measuring in both high demanding marine and industrial applications, the product range is expanded with a Coriolis Mass Flowmeter.

Our experts are

standing by■

Our products are designed to enhance fuel efficiency, ensure environmental compliance and optimize maritime operations. Discover more.

Gerard Oskam | Area Manager

What is the primary purpose of the United States Coast Guard requiring ShaPoLi in U.S. waters?

The primary purpose of the United States Coast Guard requiring ShaPoLi in U.S. waters is to reduce greenhouse gas emissions and improve fuel efficiency in maritime operations. This requirement aligns with international maritime standards, such as those established by the International Maritime Organization (IMO), to address climate change and environmental concerns. By limiting shaft power, vessels operate more efficiently, reducing fuel consumption and environmental impact. The regulation also promotes sustainability in the shipping industry, encouraging the adoption of greener technologies and practices. Ultimately, it contributes to the United States’ broader goals of reducing carbon emissions and protecting marine ecosystems.

How does ShaPoLi help in achieving maritime emission and fuel efficiency standards?

The primary purpose of the United States Coast Guard requiring ShaPoLi in U.S. waters is to reduce greenhouse gas emissions and improve fuel efficiency in maritime operations. This requirement aligns with international maritime standards, such as those established by the International Maritime Organization (IMO), to address climate change and environmental concerns. By limiting shaft power, vessels operate more efficiently, reducing fuel consumption and environmental impact. The regulation also promotes sustainability in the shipping industry, encouraging the adoption of greener technologies and practices. Ultimately, it contributes to the United States’ broader goals of reducing carbon emissions and protecting marine ecosystems.

Are there specific vessel types or sizes that must comply with the ShaPoLi requirement in U.S. waters?

The primary purpose of the United States Coast Guard requiring ShaPoLi in U.S. waters is to reduce greenhouse gas emissions and improve fuel efficiency in maritime operations. This requirement aligns with international maritime standards, such as those established by the International Maritime Organization (IMO), to address climate change and environmental concerns. By limiting shaft power, vessels operate more efficiently, reducing fuel consumption and environmental impact. The regulation also promotes sustainability in the shipping industry, encouraging the adoption of greener technologies and practices. Ultimately, it contributes to the United States’ broader goals of reducing carbon emissions and protecting marine ecosystems.

What international standards or agreements influenced the United States Coast Guard’s decision to enforce ShaPoLi?

The primary purpose of the United States Coast Guard requiring ShaPoLi in U.S. waters is to reduce greenhouse gas emissions and improve fuel efficiency in maritime operations. This requirement aligns with international maritime standards, such as those established by the International Maritime Organization (IMO), to address climate change and environmental concerns. By limiting shaft power, vessels operate more efficiently, reducing fuel consumption and environmental impact. The regulation also promotes sustainability in the shipping industry, encouraging the adoption of greener technologies and practices. Ultimately, it contributes to the United States’ broader goals of reducing carbon emissions and protecting marine ecosystems.

How will the United States Coast Guard monitor and enforce compliance with ShaPoLi requirements in U.S. waters?

The primary purpose of the United States Coast Guard requiring ShaPoLi in U.S. waters is to reduce greenhouse gas emissions and improve fuel efficiency in maritime operations. This requirement aligns with international maritime standards, such as those established by the International Maritime Organization (IMO), to address climate change and environmental concerns. By limiting shaft power, vessels operate more efficiently, reducing fuel consumption and environmental impact. The regulation also promotes sustainability in the shipping industry, encouraging the adoption of greener technologies and practices. Ultimately, it contributes to the United States’ broader goals of reducing carbon emissions and protecting marine ecosystems.